Menene karshen stub? Yaya ya kamata a yi amfani da shi? A wani yanayi kuke amfani da shi? Sau da yawa mutane suna da irin waɗannan tambayoyin, bari mu tattauna su tare.

Ana yawan amfani da ƙarshen stub tare dacinya hadin gwiwa flangedon samar da madadinwaldi wuyansa flangedangane, amma tuna cewa ba za a iya amfani da matsayin walda wuyan flange, kuma ba za a iya rude.

TSUB KARSHEN IRU

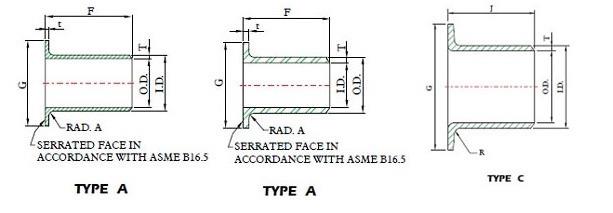

Akwai nau'ikan stub na gama gari guda uku, wato nau'in A, nau'in B da nau'in C

1. An ƙera nau'in A kuma an ƙera shi don dacewa da daidaitattun flange na haɗin gwiwa (dole ne a yi amfani da samfurori guda biyu a hade).

Fuskokin mating ɗin suna da bayanin martaba iri ɗaya don ba da izinin ɗaukar fuskar walƙiya mai santsi

2.Nau'in B dole ne a yi amfani da shi tare da daidaitattun zamewa-on flanges

3. Ana iya amfani da nau'in C ko dai tare da flange haɗin gwiwa na cinya kozamewa a kan flangeskuma ana kera su daga bututu

Akwai nau'ikan stub iri biyu, gajere da tsayi, kuma matsakaicin girmansa zai iya kaiwa inci 48, wato, nau'ikan nau'ikan DN15-DN1200.

Gajeren tsari, wanda ake kira MSS-A stub ya ƙare

Dogon tsari, wanda ake kira ASA-A stub ends ko ƙarshen stub na ANSI.

FA'IDODIN KARSHEN KUTU

1. Ƙarshen stub zai iya rage yawan farashi na haɗin gwiwar flange na tsarin tsarin bututun kayan abu mai girma, saboda flange na cinya ba dole ba ne ya yi amfani da abu ɗaya kamar bututu da gajeren ƙarshen, kuma za'a iya zaɓar ƙananan kayan aiki. don daidaitawa.

Ƙarshen 2.Stub yana haɓaka tsarin shigarwa saboda za'a iya jujjuya flanges na cinya don sauƙin daidaitawa na ramukan ƙusa.

Za'a iya yin oda ƙarshen stub tare da ƙare daban-daban

- Beveled Ƙarshe

- Ƙarshen Ƙarshe

- Ƙarshen Flanged

- Ƙarshen Ƙarshe

- Zaren Ƙarshen

APPLICATION

1.The stub karshen, wanda shi ne ainihin guntu na bututu, tare da daya karshen flared waje da sauran shirya da za a welded zuwa wani bututu na wannan rami size, abu da kauri bango.

2.A cinya hadin gwiwa flange, wanda ake amfani da su a zahiri toshe tsawon biyu na bututu tare.

Lokacin aikawa: Yuni-06-2023